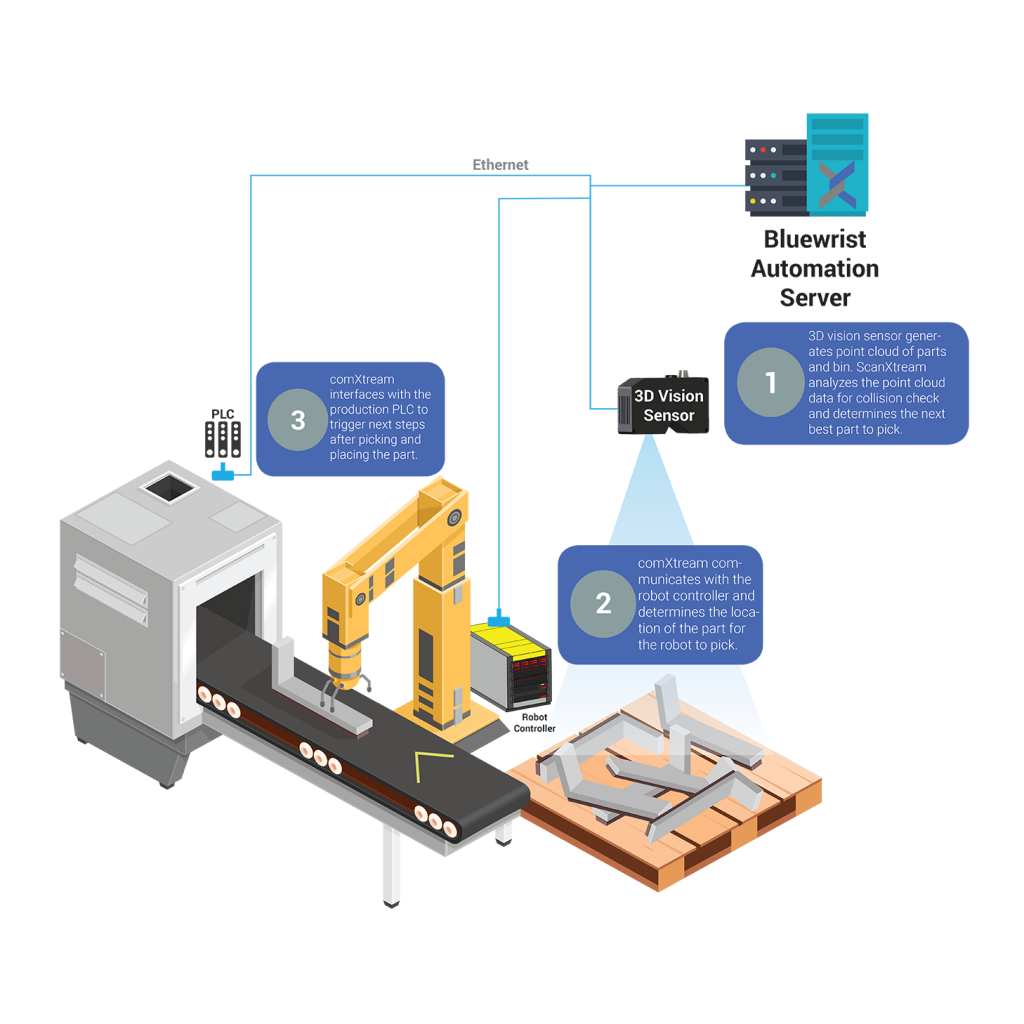

FlexiPick is an advanced 3D vision robot guidance solution that allows a robot to pick up parts randomly placed in a bin (bin-picking) and present them to the assembly process or to locate a part to pick and place accurately. Using stationary or robot-mounted cameras, Bluewrist software uses a rich library of 3D vision and AI algorithms and strategies to accurately and instantaneously match the scans to the part model either CAD or scanned.

A typical configuration includes a robot with a gripper, a 3D camera (stationary or robot-mounted), a Bluewrist controller hosting the software, and an artifact for hand-eye calibration.

FlexiPick is also used for other assembly and machining guidance processes such as weld guidance, glue dispensing, hole drilling, cutting, bolt tightening, etc.

FEATURES

- Compares scan to the CAD or scan model and returns all possible gripping/matching configurations

- Includes many 3D machine vision & AI algorithms for matching and detection for robot guidance

- 3D machine vision & AI engine, Real-time 3D engine using shape-based matching and deep learning for part localization

- Achieves a high system accuracy, using millions of scan points

- Short processing time, within production cycle time

- Automated hand-eye calibration using Bluewrist calibration artifacts

- Includes comprehensive reach and collision analysis modules to check the accessibility and clearance of the new robot path

- Offers many user-friendly features including password protection, logging, automatic backup, cleanup and updates, etc.

- A unique user-friendly interface for many industrial applications

- No coding is required, everything is set through a graphical interface

- Offers user-customizable and managed logic to the PLC including a built-in ladder logic module

- A built-in communication and control library for most PLC, vision systems, and robot controllers

- Supports multiple industrial communication protocols, including; A-B Ethernet/IP, ProfiNet, A-B Ethernet for PLC5/SLC500/MicroLogix, Modbus/TCP Master, OPC Data Access, and MQTT

- Easy recalibration of the sensor and gripper

- Additional user frame calculation methods (best-fit, 3-2-1 fixturing, formulas interpreter) with an unlimited number of custom user frames available for use

- A user-friendly graphical interface allowing line users to modify offsets

- Averaging and history of user frames sent to the robots

- Detects and if needed eliminates errors due to part positioning, local part defects and scan noise.

BENEFITS

- Automated gripping, machining, and assembly tasks for parts of any shape and size

- Reduced part sorting costs and improved overall system productivity

- Full integration into the production line

- Speedy processing and customized to fit production line cycle time constraints, ensuring a consistent cycle time

- Short return on investment

- Reduced labor costs by automating material handling tasks

- Elimination of repetitive and painful operations for operators: heavy parts, noise, health hazards…

- Ensuring a repeatable positioning and eliminating costly fixtures and racks

- Improved process quality and reduces manual programming time

- Ensured a repeatable process even with parts having local defects

- Alarms in case a robot reaches or processes issues

Bluewrist Advantage

A high performance and reliable random bin picking solution requires seamless integration of software, 3D vision sensors and robotic guidance. Powered by custom software that is precisely calibrated to the physical characteristics of the part and tailored to meet a manufacturers’ cycle time requirements, FlexiPick seamlessly integrates into the customer’s existing production process. This enables Bluewrist’s FlexiPick solution to overcome technical challenges and deliver a superior solution.

High Performance Bin Picking

- Uses 3D vision camera to ensure high speed repeatable bin picking performance

- Vision system is not affected by changes in ambient lighting condition

- Reliable operation even when the bin is full or nearly empty

- Hardware agnostic solution with customizable sensor selection to suit the part’s physical characteristics

Applications

Typical Parts

- Molded, forged, stamped, and machined parts

- Parts with complex or simple geometries: tubular, spherical, flat

Assembly and Material Handling Applications

- Random bin picking

- Racking and de-racking

- Palletizing and de-palletizing

- Door, hood, lift gate, roof, and trunk lids insertion and installation

- Wheel loading

- Glass insertion into the apertures (windshield, side windows, sunroof, etc.)

- Seat installation

Machine Applications

- Welding

- Cutting

- Dispensing

- Punching

- Deburring

- Drilling

- Grinding

- Milling

- Riveting