Reduce & Eliminate Downstream Defects with Bluewrist

Our turn-key solution offers a 100% 3D inspection of automotive B-side door panels before final delivery to the OEMs. With the use of a 3D camera and robot, our system performs a complete scan of the door panel to verify the correctness of the installed parts such as clips, screws, fasteners, foam and weld. Confirming the presence and correct installation of the parts of automotive door panels is crucial to the quality of the final door assembly and to prevent the delivery of defective parts to the manufacturer.

Fully Integrated Solution

Our Door Panel Inspection Solution is fully integrated and deployable alongside your existing assembly line:

- Reduces Trouble Report issued by OEM due to quality issue

- Supports automated 100% features inline inspection, not missing bad parts

- Provides dimensional measurement and a variety of defect detection, not just presence check

- Offers traceability and Statistical Process Control (SPC) for assembly quality analysis

Powerful Inspection Capabilities

The Bluewrist Door Inspection Solution can quickly and reliably analyze the following features to ensure defect-free delivery to your customer:

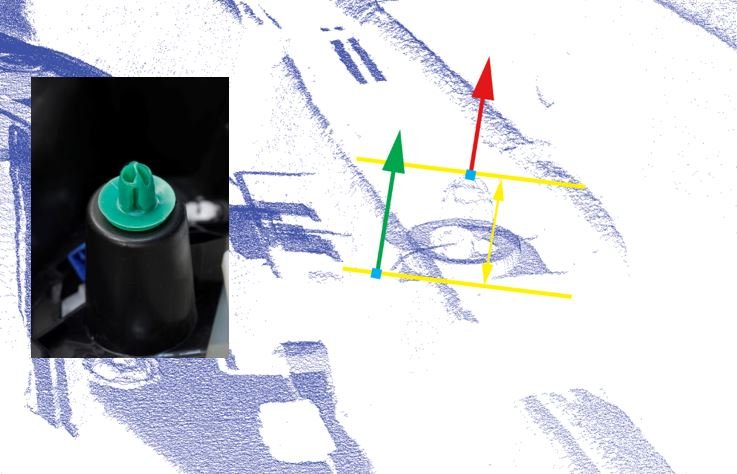

3D Point Cloud Processing and Analysis of Scanned Feature – Checking Clip Height Insertion

Door Panel Inspection with 3D Vision

The Bluewrist Door Panel Inspection Solution uses a high-resolution laser profile scanner powered by our NIST-Certified ScanXtream software to scan and analyze different features to detect variances and out of tolerance installations. This analysis includes challenging features with low contrast, such as white plastic welds.

Plastic Weld Point Cloud

Plastic Weld Photo

The ScanXtream point cloud processing software provides users a visual indication of defects in the weld, based on users’ configured datum and welding standard parameters. Inspection data and images can be saved for future reporting, record keeping and review purposes as part of a comprehensive quality assurance program.

Real-time Insight Into Your Manufacturing Process

By checking every feature throughout the manufacturing process, trends and custom alarms will inform you of potential problems before it leads to defects:

- In this SPC chart on the right, the screw insertion height is trending upwards into the custom limit that triggers a warning

- Operators are alerted and can correct potential issues that may lead to a defect such as worn screw bits, lack of hydraulic pressure, etc.

Technical Specifications:

- Cycle Time – 0.3 sec/feature (average)

- Feature Types – clips, screws, fasteners, foam and plastic weld

- Resolution – 0.1 mm

Predictive Defect Analysis and Notification