Rising Importance of Robot Calibration

KinOptim is a complete robot calibration solution fully integrated with comXtream .

As industrial robots are increasingly used in high precision applications such as welding, drilling, dispensing and guidance related assembly tasks, maintaining robot volumetric accuracy and drift are essential at ensuring final product quality and reliability in the production process.

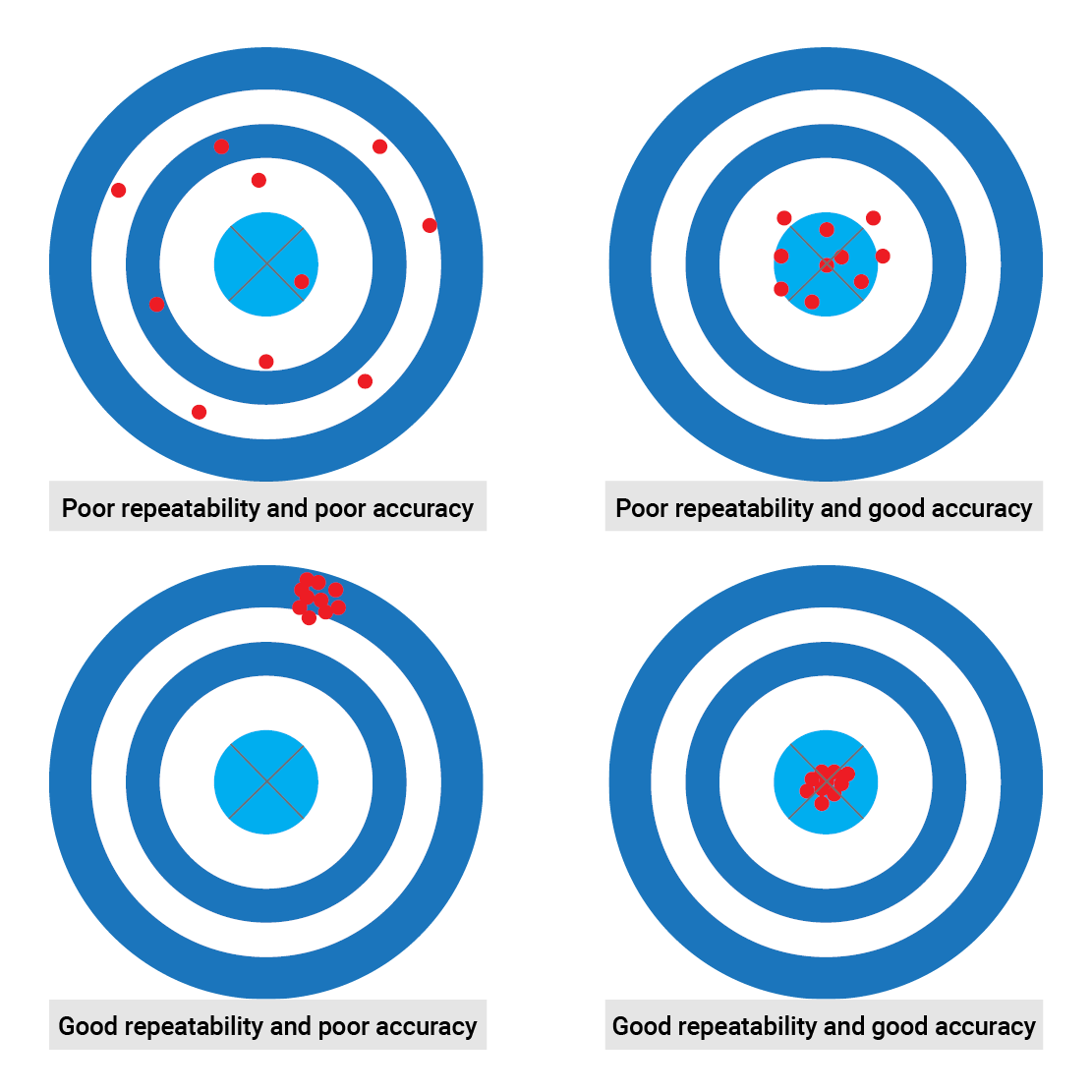

Volumetric accuracy and repeatability is a measure of the robot’s ability to move to a specified location with minimal deviation or variance. Through calibration, both absolute and volumetric accuracy can be improved to enhance process stability.

Many factors can affect the accuracy and performance of an industrial robot

Factors Affecting Robot Accuracy

High accuracy is the most difficult to maintain in an inline production environment as many factors such as temperature, joint friction, weight loading and manufacturing tolerances may cause the robot to deviate from its desired preprogrammed path. This can lead to potential product quality issues and increased costs associated with scrap parts.

| Volumetric & Temperature Calibration |

|---|

|

| ISO 9283 Robot Performance Analysis |

|---|

|

Bluewrist KinOptim Robot Calibration Solution

KinOptim is a complete inline robot calibration software solution developed by Bluewrist to help improve and maintain robot accuracy in the production process. KinOptim automatically compensates for robot geometric parameters and updates them without user intervention. Our software also calculates and compensates for the robot user frame and tool frame as part of an automated robot monitoring and performance measurement suite.

Pre and post calibration result of a popular collaborative robot

Features

- Very easy to use and to recover

- Doesn’t require a certified artifact

- Offers process repeatability within 0.1mm

- Uses many parameters including robot D-H kinematic links, TCP, base and gravity effects

Applications

- Offline programming compensation

- Volumetric accuracy for robot guidance

- Inspection temperature compensation

- Continuous TCP calibration