Reduce & Eliminate Defects With Bluewrist

Plug and Play inline 3D Inspection

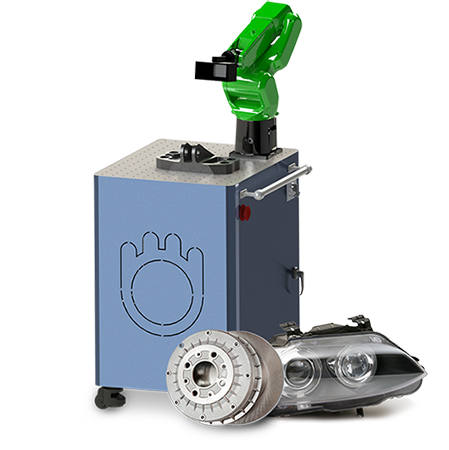

A plug and play metrology-grade non-contact 3D scanning and flexible measurement system is finally within reach for manufacturers of all sizes and industries. Elevate quality control to the next level with the Bluewrist PreciScan3D Inspection Station.

With out-of-the box 3D scanning and dimensional measurement capabilities, Bluewrist PreciScan3D Inspection Station can be rapidly deployed for in-line, near-line or off-line applications for manufacturing quality control. With a scanning accuracy of up to 0.1mm, our solution can be used to detect, analyze, and inspect various features on manufactured components that are critical to the final product quality.

Bluewrist PreciScan3D Inspection Station combines flexibility, functionality, and performance to help manufacturers conduct thorough inspections to prevent quality defects. The integrated solution is deployed on a rugged cart for maximum mobility within the manufacturing site. Using a high resolution 3D laser scanner mounted on a collaborative robot, the PreciScan3D Inspection Station is designed to work alongside your production staff to gather critical real-time actionable quality control data.

The PreciScan3D Inspection Station is a full-fledged mobile quality control station that can be used to check manufactured parts anywhere within the production process with minimal delay or transfer to an off-site lab. The system comes preloaded with industry proven software such as comXtream, ScanXtream, and SPCWorks, making it possible to conduct on-site part analysis, inspection, and verification against predetermined quality criteria.

With PreciScan3D Inspection Station, quality control staff are empowered to make rapid data-driven decisions to improve product quality and eliminate potential downstream defects.

REDUCE DEFECTS AND IMPROVE QUALITY

FLEXIBLE NON-CONTACT INSPECTION & HIGH RESOLUTION 3D LASER SCANNING

- High resolution 0.1mm scanning accuracy – captures highly accurate 3D surface features for comparison against CAD models or GD&T datum reference frames

- Inspect and scan complex parts with high accuracy and repeatability – robot mounted 3D laser scanner provides complete coverage of part to generate detailed point cloud models for further analysis

- Part surface defect and dimensional variation detection – automatically alerts users when quality issues are detected

POWERED BY INDUSTRY PROVEN SOFTWARE (SPCWORKS)

PREDICTIVE ANALYTICS FOR DEFECT PREVENTION

- Prevent defects at the source – detects and reports deviations in dimensional variations and takes preventative action to minimize defects

- Monitor and analyze trends in the production process – statistically analyzes dimensional data for all scanned parts and automatically notifies users of deviations from predetermined tolerances

- Real-time quality data to improve traceability – in-line or near-line deployment to gather real-time quality data for rapid decision making

WORK ALONGSIDE NOT ALONE

SAFETY & FLEXIBLE DEPLOYMENT

- No safety barrier or custom designed cell required – collaborative robot designed to work alongside quality control staff near the production line

- Minimal integration and custom configuration – out-of-box plug and play 3D scanning and inspection capabilities

- Maximum portability and small foot print – can be deployed anywhere within the manufacturing facility for on-site inspection and scanning

SCANNING & GD&T INSPECTION CAPABILITIES

AUTOMATED DIMENSIONAL DATA CONTROL AND REPORTING

| GD&T INSPECTION CAPABILITIES | SURFACE FEATURE INSPECTION |

|---|---|

|

|

| DATA COLLECTION & REPORTING FOR TREND ANALYSIS |

|---|

|

SPC OVERVIEW

GRAPHICAL OVERVIEW

CONTROLS CHARTS AND HISTOGRAMS

|