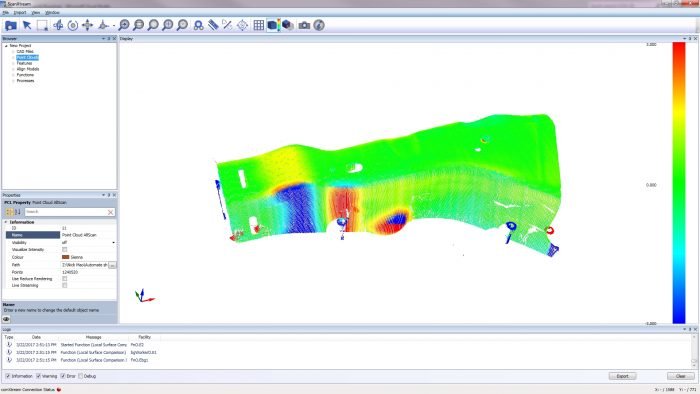

ScanXtream is a user-friendly 3D point cloud processing and viewing software that is provided as a stand-alone application or bundled with comXtream.

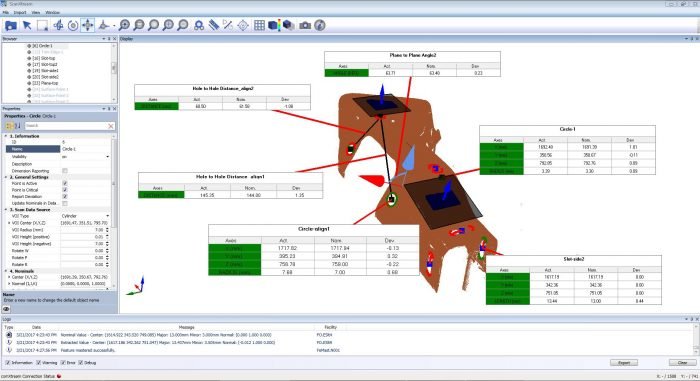

Designed as an inline inspection software, ScanXtream is optimized for use in fast paced manufacturing environments and offers accurate, efficient and stable performance. Our software can effortlessly process large amount of high resolution data streamed from multiple 2D and 3D vision cameras in real-time to perform the inline 3D scanning and dimensional measurements of manufactured components against GD&T and CAD specifications.

Features

- Supports:

- CAD files (IGES, STL, VRML, etc.)

- Data streamed from comXtream

- 3D point clouds from 3rd party software

- Many Alignment Strategies:

- 6 D.O.F. point cloud to CAD alignment (point cloud best-fit, feature-based N-Point best-fit, 3-2-1 alignment)

- 6 D.O.F point cloud to point cloud alignment (point cloud stitching, reference point cloud alignment)

- Exports :

- Point clouds (DAT, XYZ, BIN, etc.)

- Depth images (PNG, JPEG, BMP, etc.)

- Generate CAD from point clouds (STL)

- Data streamed to comXtream, API

- Extracts:

- Holes, Ellipse, Arc, Squares, Slots (x, y, z, i, j, k, D1, D2),

- Spheres (x,y,z),Cylinders (x,y,z,i,j,k,D1,D2)

- Planes (Flatness, i,j,k),Lines (i,j,k), Squardness (Angle)

- Surface points, Corner, Edge (x, y, z)

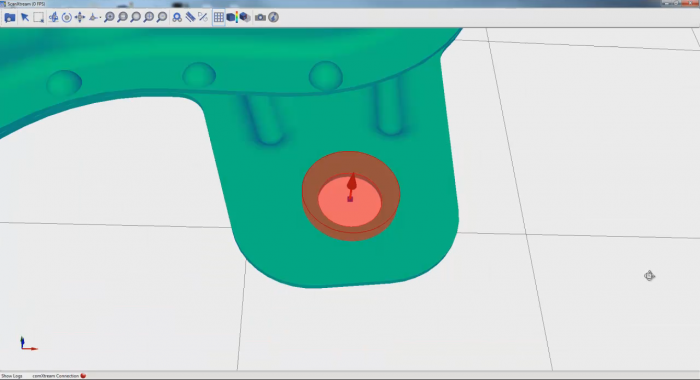

- Surface defects (Color map and Accept/Reject)

- Studs (Accept/Reject)

- Volumes

- Beads (W, L, H, discontinuity, position)

- Welds (W, L, H, Cracks, Undercut and overlap, Spatter, Porosity, Underfill and overfill, Welding debris)

- Other Features

- Ability to manage large files (store, organize, auto-delete)

- Data saved into Microsoft SQL database

Applications

- Production

- Engineering

- Quality assurance