Fast ROI Through Labor Cost Reduction and Productivity Increase

Engineer, Design or Upgrade Complete Bin Picking Solutions

Identify Parts Position and Orientation with High Reliability Through 3D Vision

Past Processing and Part Pick Time to Meet Cycle Time Requirements

Our team at Bluewrist can help automate existing manual process with our turn-key random bin picking solution.

CONTACT US FOR MORE INFORMATION

Leader in Random Bin Picking Solutions

Bluewrist can help automate existing manual loading and unloading process through random bin picking. We have implemented many successful systems for parts such as brake rotors, stamped metal components or vehicle axles at many manufacturing facilities across North-America.

Reliable & High Performance Bin Picking Solution

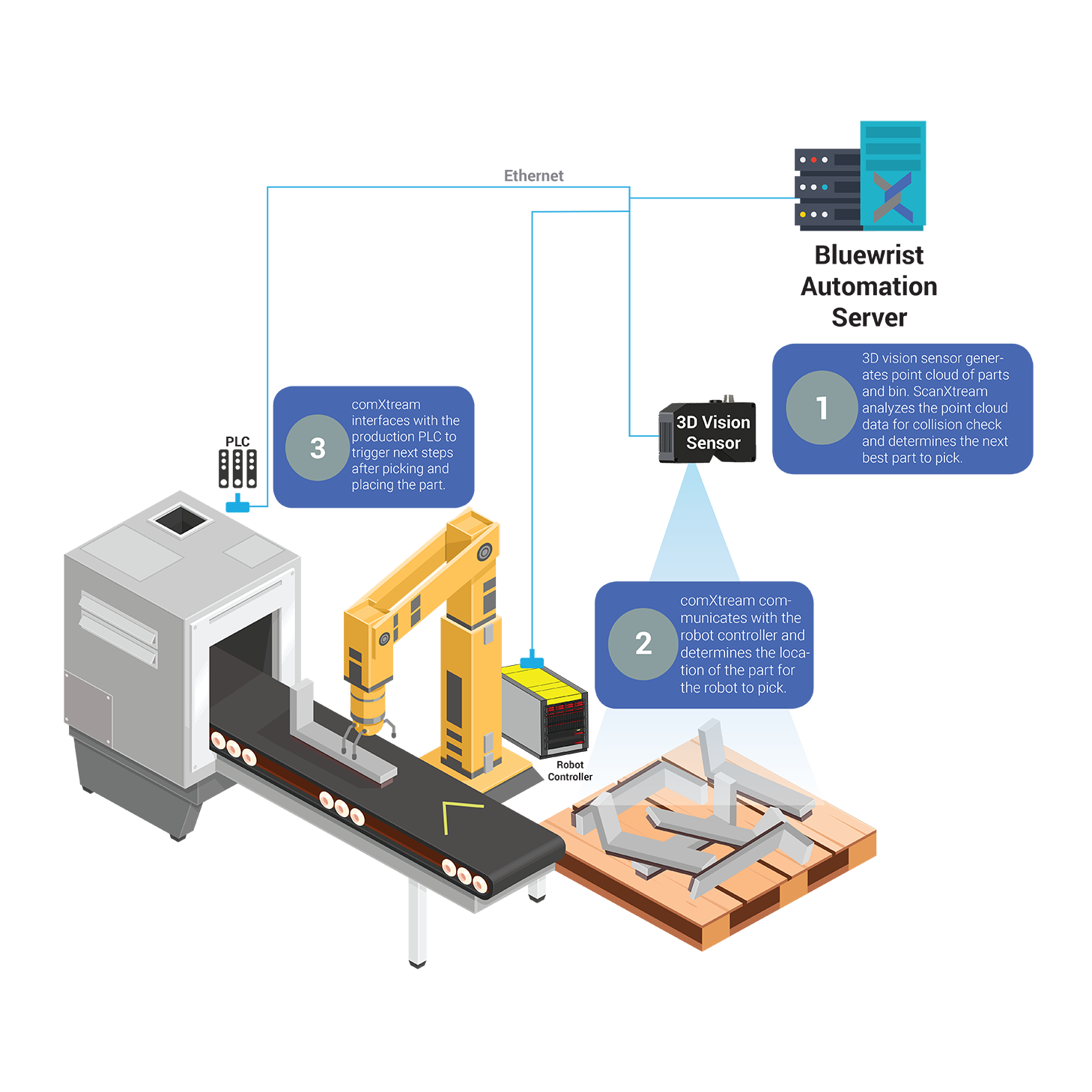

- Uses 3D vision camera to ensure high speed repeatable bin picking performance

- Reliable operation even when the bin is full or nearly empty

- Vision system is not affected by changes in ambient lighting condition

- Powered by Bluewrist software for exceptional compatibility and reliability

Upgrade Existing 2D Based Bin Picking Solution

Depending on your needs, our engineering team can help you design or modify existing solution and is powered by Bluewrist 3D vision software. This tight integration of software and hardware ensure that our bin picking solution is highly reliable with fast pick time to meet the cycle time requirements of your operations.

Bluewrist Engineering and System Integrations Expertise

For close to 15 years, Bluewrist has been a leader in developing innovative industrial automation, robotics, and 3D vision solutions for modern factories worldwide. From hardware to software, we have the in-house expertise to design and engineer a complete bin picking solution from scratch and integrate it into the existing production process.

Bluewrist Bin Picking Solutions Advantage

A high performance and reliable random bin picking solution requires seamless integration of software, 3D vision sensors and robotic guidance. Powered by custom software that is precisely calibrated to the physical characteristics of the part and tailored to meet a manufacturers’ cycle time requirements, our solution seamlessly integrates into the existing production process.

- High reliability and low maintenance

- Hardware agnostic solution with customizable sensor selection to suit the part’s physical characteristics

- Fast part detection and pick coordinates calculation to meet cycle time requirements

- Flexible system that can be re-programmed for new parts based on production needs

Download our brochure to learn more.

Learn how a Tier-1 auto parts supplier successfully implemented a random bin picking solution that picks vehicle axles from a metal bin and position it onto a feeder system for downstream processing.

The benefits of working with Bluewrist:

- Software & Hardware Expertise – A reliable bin picking solution requires both the hardware such as robots, PLCs and 3D vision sensors to work seamlessly with the software components. Bluewrist offers one-stop shop and has the in-house expertise to accomplish both and deliver a superior solution

- Experienced North-American Engineering Team – Our mechanical and application engineering team members are located in Canada and the United States to offer you excellent on-site technical support during ramp-up and deployment