Advantages of technical thermoplastics over metals in battery housings for electric vehicles

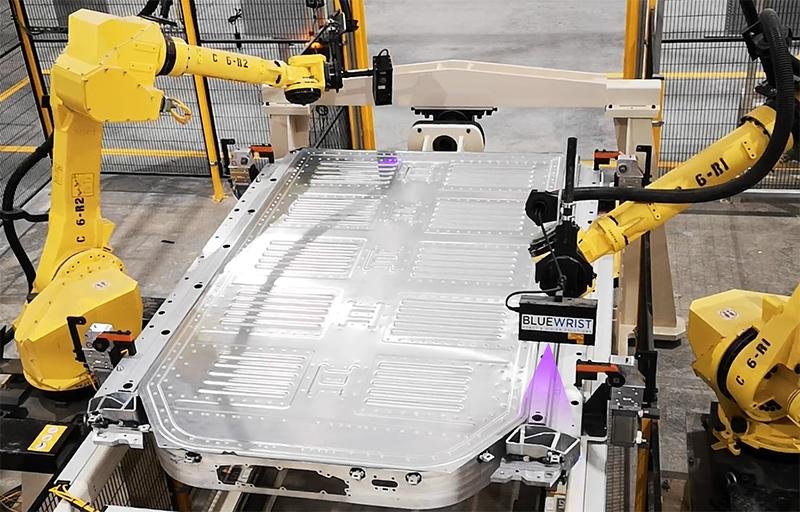

This article is related to the development of composite materials and its potential use in battery housing for the electric vehicles (EV). Bluewrist has deployed proven 100% inline 3D inspection solution for the EV battery tray market and is well suited to help inspect the next generation of lightweight, strong and corrosion resistant composite EV battery trays.

Read the full article on – Read the article on Composites World

Article Highlight:

“Today, says Lanxess, housings for high-voltage batteries are primarily made of extruded steel or aluminum profiles. Depending on the vehicle class, the housing length and widths can be well over 2,000 or 1,500 millimeters”

“The size, the number of components and the numerous manufacturing and assembly steps make metal housings very cost intensive. For example, complex structures made from strand press profiles require many secondary work steps such as welding, punching and riveting.”