Bluewrist 3D Inline Weld Inspection

Reduce downstream weld defects and reworks with inline weld checkFast ROI through reduction in QA inspection and rework cost.

Reduce downstream weld defects that may lead to safety recalls.

Full traceability and insights into your welding process.

Achieve 100% inline inspection of all your parts and weld features.

CONTACT US FOR MORE INFORMATION

Bluewrist’s weld inspection solution improves quality by eliminating manual welding inspection that are prone to inspector error and subjectivity. Automated weld inspection helps achieve 100% accuracy and consistency by comparing weld characteristics against a predetermined quality standards intended for use in each unique industry or application.

Multiple Inspection Features

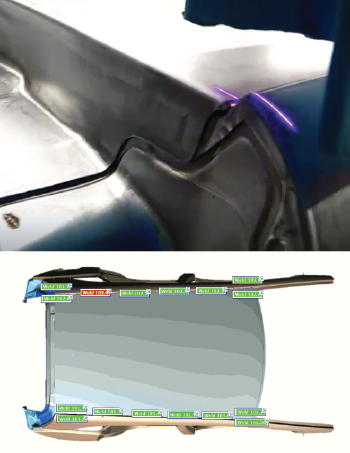

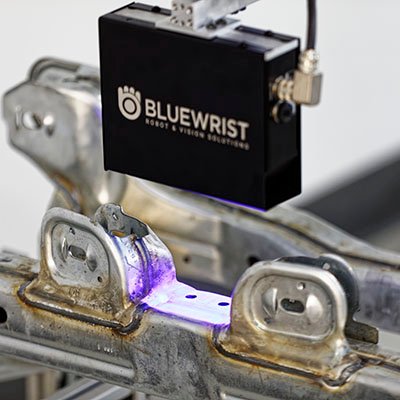

Bluewrist weld inspection solution uses a 3D profiler or 3D snapshot sensors such as the Gocator® 3D smart sensors to capture detailed surface characteristics of the weld in question. The weld profiles can be inspected in its entirety or broken down into individual sections for analysis and comparison against welding blueprints to guarantee conformity in the following areas:

- Weld Length

- Weld Width

- Theoretical Throat Thickness

- Leg Length

Weld Type Suitability

- Fillet welds

- Lap welds

- Butt weld

- Corner weld

- T-joint weld

- Plug weld

Real-Time Weld Defect Detection, Reporting and Visualization

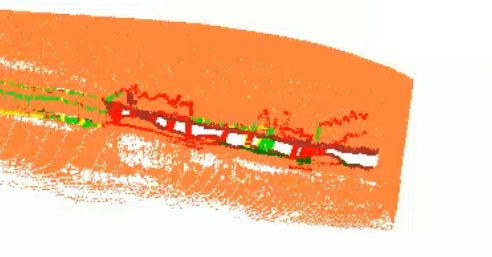

High resolution laser scanning makes Bluewrist weld inspection solution the ideal method to detect and analyze different surface weld defects that may lead to expensive and time consuming rework such as:

- Spatter

- Porosity

- Cracks

- Undercut and overlap

- Underfill and overfill

- Welding debris

- Discontinuity

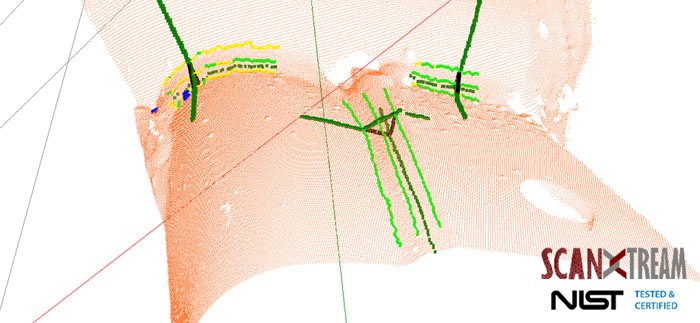

ScanXtream point cloud processing software gives user a visual indication of defects in the weld based on user configured datum and welding standard parameters. Inspection data and images can be saved for future reporting, record keeping and review purposes as part of a comprehensive quality assurance program.

Flexible Inspection Deployment

Bluewrist 3D weld inspection solution can be configured or modified based on the changing requirements of the manufacturing facility:

Multiple Configuration Options:

- Robot Mounted Weld Inspection –Flexibility for inspecting complex weld patterns or large parts

- Stationary Mounted Weld Inspection – High speed weld inspection in mass production environment

- Linear Slide – Repeatable inspection for predetermined weld inspection at a specific location

Bluewrist & LMI Weld Inspection Success Stories

Bluewrist 3D weld inspection solution can help you achieve 100% inline inspection of all critical weld features to prevent downstream defects. Our solution is field proven and is currently in use at major OEMs performing inline inspection of roof seam welding and electric vehicle battery tray weld inspections. In addition, OEMs use our solution to check weld quality in the following areas:

- Vehicle seat frame weld

- Suspension cradle weld

- Plastic weld quality in interior trims

- Vehicle trailer hitch weld

- Weld on vehicle body

- Transmission parts weld

Download the case studies on the left to learn more about our customer success stories in weld inspection.

Don’t Leave Weld Inspection to Chance

Modern manufacturing joining process requires hundreds of weld features or centimeters of continuous weld to guarantee final product quality. Manual visual inspection using gauges is insufficient and greatly increases the risks of passing defective weld downstream. Undetected, these defects can lead to catastrophic product failures or expense product recalls.

Learn why it is important to upgrade your existing manual weld inspection to a fully automated inline solution from Bluewrist!