Bluewrist Case Study

Robot GuidanceAutomated Wheel Installation

The Application

Our client in the automotive sector approached us to improve the wheel installation processes in its factory. Our client was using a manual system that required four workers to pick-up and mount each tire on the rotor; two workers would work on each side of the wheel during the installation process.

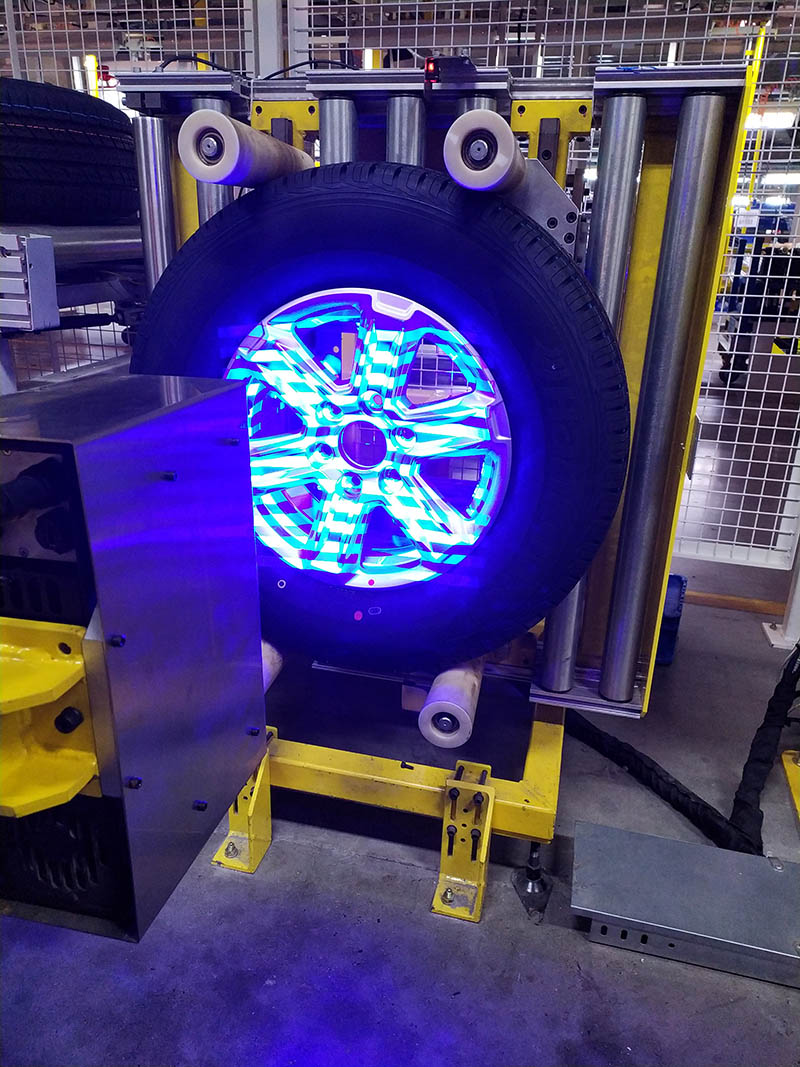

Using a structured light camera to capture the point cloud of the rotor

The Challenge

There were a number of challenges to address when designing an application that would improve performance, process, and quality. These challenges relate to both the rotors and the processes involved in fitting the tires.

- Over 60 different rims are used with different types of surfaces (dark, matte, glossy), which makes 2D camera systems difficult to implement because of the effect of lighting solutions on the different types of surfaces.

- The bolts are preinstalled on each router. Each bolt cap has a small surface area, which means a 3D,high-resolution vision system is essential to accurately locate the point cloud for each bolt cap.

- During installation, the rotor has a random rotation, which means that the bolts are in a different position for each installation, requiring a solution that will for and identify the bolt location.

- Because the rotor can rotate up to 15 degrees in both directions along the car, the solution also needs to be able to achieve 3D matching or a large point cloud.

- In addition to these technical factors, the part is heavy, and the cycle time is limited, with only 3.5 seconds available for the full point cloud grab and process.

The Solution

We implemented the Bluewrist 3D Vision Robot Guidance solution using two Fanuc robots with a seven-axis linear slide and high-resolution blue structure light snapshot 3D cameras. Using this system and the ScanXtream and comXtream software, the point clouds of the wheel and the rotor are matched to the corresponding CAD model with remarkable accuracy. Our vision system can achieve +/‒ 0.3 mm accuracy in XYZ and +/‒ 0.3 degrees in WPR.

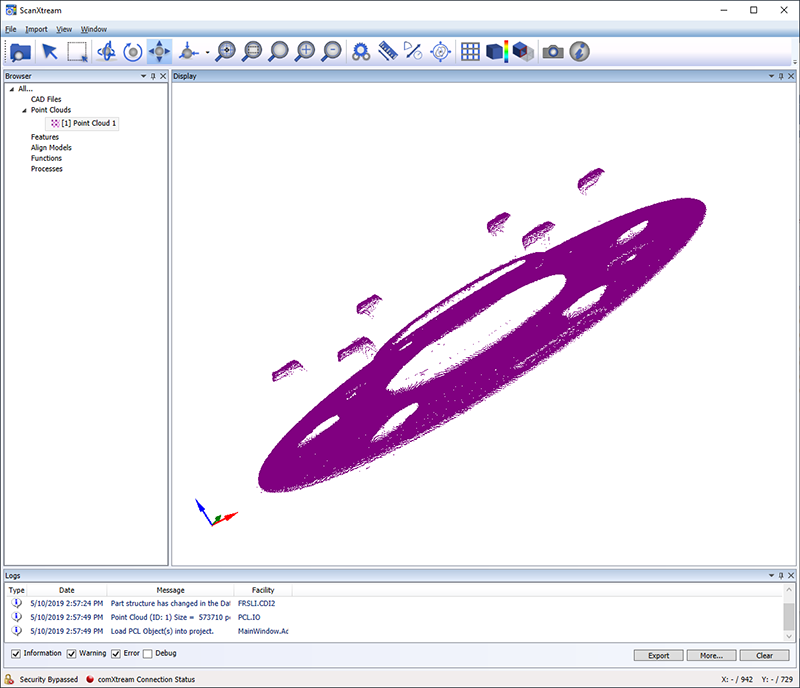

3D point cloud of the rotor

3D point cloud of the wheel and tires

The Results

Our full Bluewrist solution is scalable from a few hundred to thousands of cars per day as required by a manufacturer’s production requirements. Our client’s current production run rate is 250 cars per day, and the wheel installation system consistently achieves 99.5% uptime. The application can pick up the wheel and install it onto the rotor with multiple features covering the functionality required to process different surfaces, fitting positions, and bolts.

With a vision processing cycle time of 3.5 seconds, efficiency is much improved, the initial problems have been resolved, and the process no longer requires any worker involvement.

Please contact us for more information.

Using structured light camera to capture point cloud image of the wheel