Bluewrist Case Study

Material Handling Through Robotic Bin Picking & Process Automation

Our Client

Our customer is a global leader in the manufacture of cutting edges, wear parts, and fabrications, and is the premier commercial heat treat services provider in North America. This family owned firm has over 80 years of experience in the industry, looking after some of the most demanding customers in the world. They approached us to improve the efficiency and quality of the manufacturing process for the 3000+ cutting edges produced every day for use on road grading machines.

The Challenge

The specific process that needed improvement was focused on the process of removing the cutting edges from pallets to place them on paint hooks which were then lifted on to an overhead gantry using a hydraulic lift table. This was time consuming, labor intensive, dangerous and introduced human error into the process. Bluewrist were asked to create a solution which would automate this process and remove the need for any human involvement with the process.

The system Bluewrist created would need to identify 80 different sized parts, the longest of which was 72”, and position these correctly on the paint hooks with an accuracy tolerance of 1mm in order to ensure the parts would be correctly dipped into the paint tank.

Solution

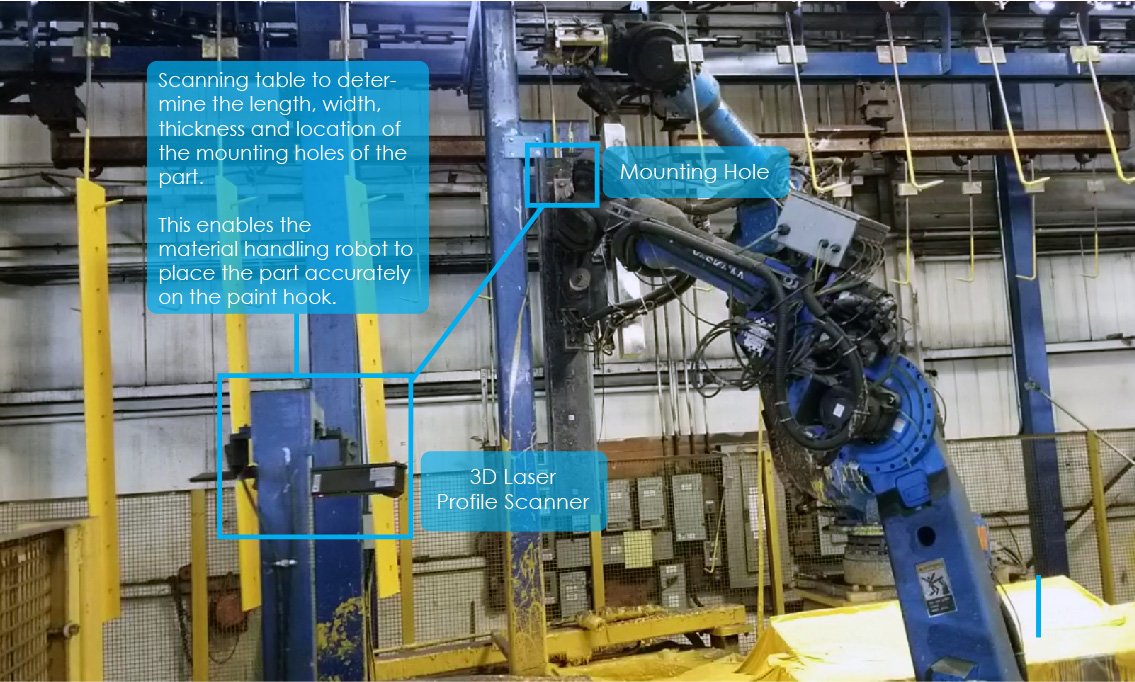

Bluewrist automation team deployed 3 pieces of technology within the factory. These included a robot mounted 3D structured light camera, 4 linear slide mounted laser profile cameras and 1 Yaskawa Motoman Material Handling Robot. Together these technologies are able to process the depalletizing and hooking through a two-stage process.

The 3D structured light camera is used to locate each part on the pallet (parts are placed in stacks on the pallet) so that it can be picked up and transferred to the scanning table. Locating the part also relies on comXtream to carry out the calculations required to provide a set of coordinates in the robot’s world coordinate system to ensure that the robot could drive its picking magnets directly to the part. Offsets were added to specific parts to ensure optimal magnet placement.

Once on the scanning table the laser profile cameras were placed at opposing angles so that the sides and the top of the part could be scanned. This creates a point cloud which can then be processed and aligned to the part’s CAD model. The amount that the part moved for the alignment to the CAD model is then used to recalculate how the material handler robot should pick up the part with a much higher accuracy (within ~1mm).

Once aligned the software is then able to identify the location of all of the holes on the part surface (3-12 depending on the part), in addition to the length, width and thickness of the part itself enabling the robot to then place the part accurately on the paint hook.