Bluewrist Case Study

Suspension Cradle Automated Quality Control InspectionAutomated Inspection System – 32 Features Per Cycle Under 13 Seconds

The Application

Suspension cradles are complex components found in every automobile. The cradle consists of several welded, high-strength hydroformed steel tubes and stamped parts. These parts have to be manufactured with precise alignment in order to support the mounting of the suspension components, differential carrier and control arm brackets.

The Challenge

A global tier 1 automotive component manufacturer needed to verify the dimensional quality of suspension cradles in an inline process. The application requires 32 feature inspections in under 13 seconds to meet high-volume cycle times and the adherence to strict GD&T (Geometric Dimensioning and Tolerance).

Any deviations in the cradle will lead to incorrectly fit components, which adversely affects the vehicle’s camber and toe angles and can result in costly rework and recalls.

The Solution

The manufacturer required a 100% inline solution that could meet production speed. Traditional CMMs (Coordinate Measurement Machine) are expensive and can take more than 40 minutes to perform the task.

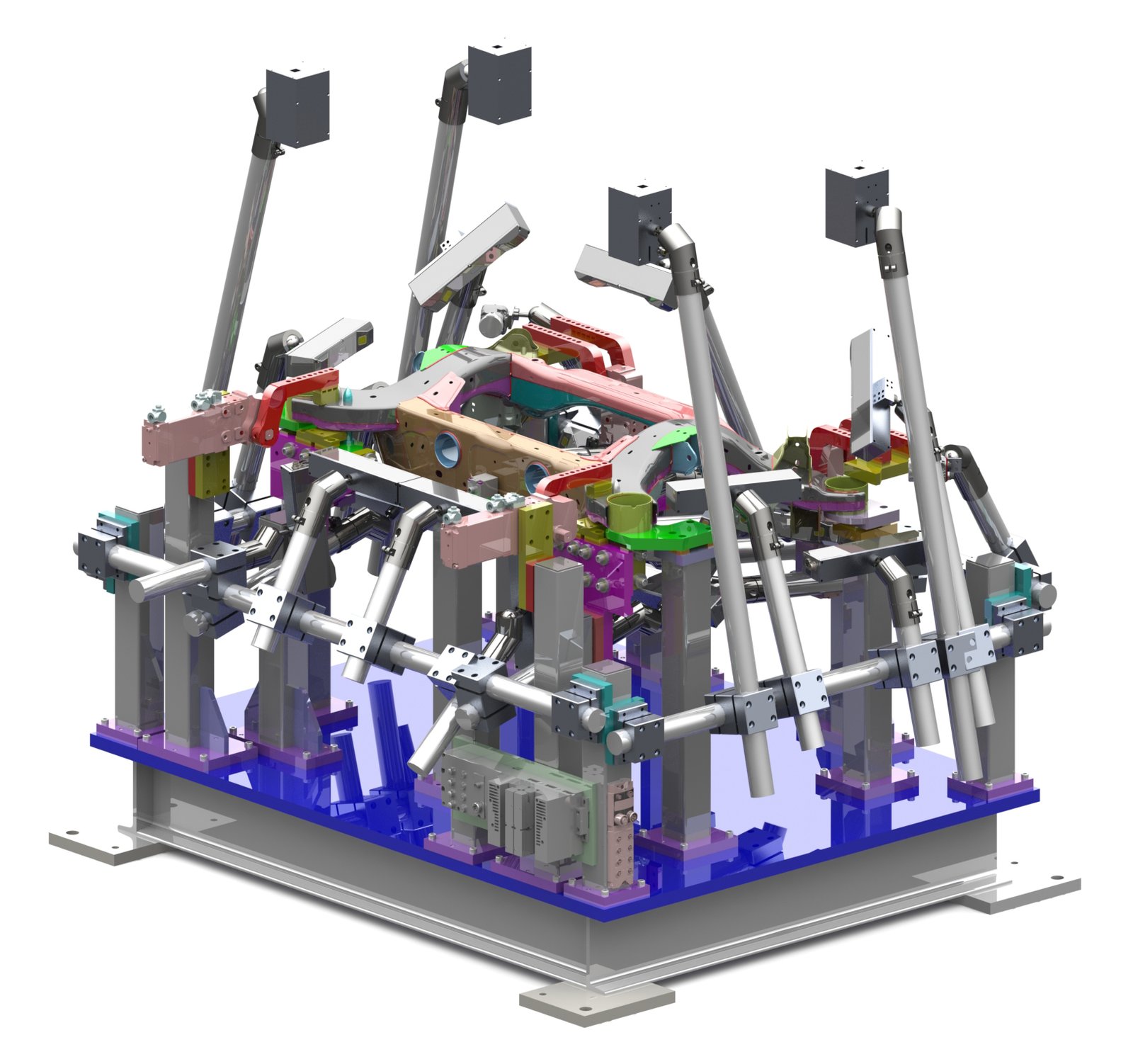

Bluewrist’s FlexiSight system uses 23 3D snapshot sensors strategically positioned on a custom designed fixture. The manufacturer is able to inspect holes, slots, studs, and trims. Scan data is compared to the CAD design and GD&T specifications.

In this system, the suspension cradle is placed, secured, inspected, and removed by a robot arm. The system also employs 2D cameras to detect basic feature presence or absence. Results are streamed in real-time to Bluewrist’s comXtream software, which processes large amounts of data from the 3D sensors. comXtream also links the sensors with the robot and PLCs.

Additionally, Bluewrist SPCWorks software monitors real-time dimensional data, and provides statistical analysis to operators in order to identify even the smallest deviations from tolerance.

The Results

If the cradle passes inspection, it is delivered to the next step of the production process. Any cradle with defects or deviations is automatically removed from the production line.

Bluewrist’s FlexiSight system is able to identify deviations from tolerances in real-time and deliver a 100% inline inspection on thousands of suspension cradles per day–all while maximizing product using automated quality control and reducing system costs.

Next Steps

The Gocator and Bluewrist FlexiSight system can be modified to inspect other vehicle models.

Points to highlight:

- Scans down to 35 µm data resolution at speeds of up to 5 Hz.

- Small form factor and lightweight industrial design make 3D sensors ideal for fitting into small spaces and mounting on robots.

- IP67-rated housing with an industrial projector offering lifetimes up to 10 years of continuous operation.

- Stereo camera technology minimizes occlusions and interference from ambient lighting.

Please contact us for more information.