Reduce & Eliminate Downstream Defects with Bluewrist

A typical vehicle seat has numerous electrical connectors for seat motors, the engine control unit, airbag, HVAC systems, sensors and safety belt warning system. The complete and correct insertion of electrical connectors is critical for the occupancy safety, and any undetected downstream defects could result in expensive recalls and high warranty claims. Bluewrist Turn-key 3D Vision Inspection Solution can perform 100% inline inspection of these electrical connectors on the seat to eliminate human error and ensure defect-free delivery to OEM customers.

Fully Integrated Solution

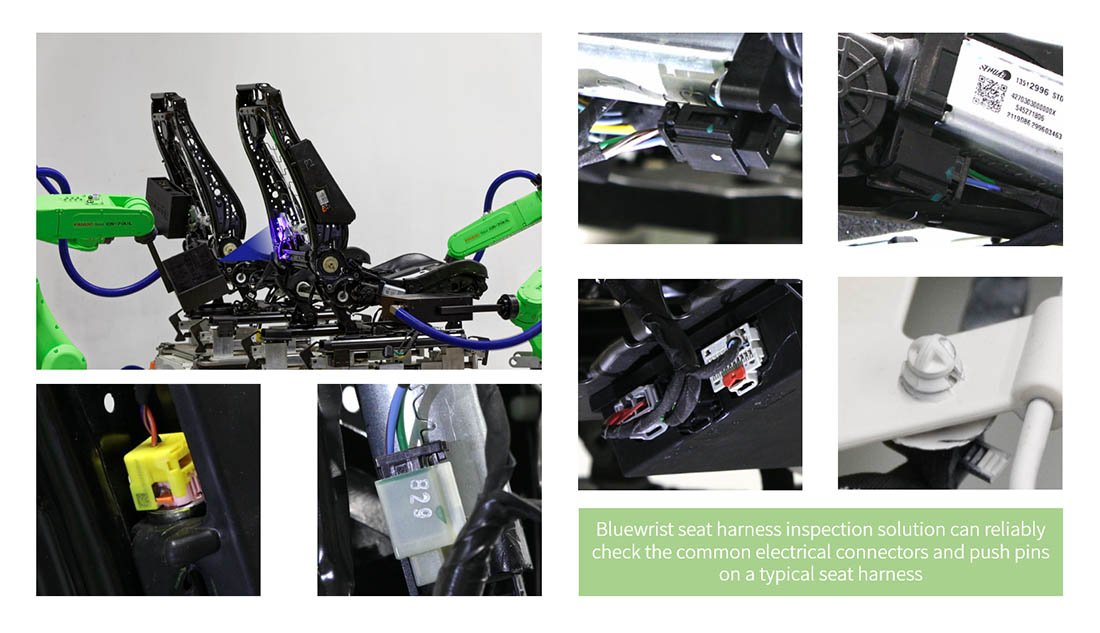

Our seat harness inspection solution can be configured with one or two collaborative/conventional robot(s) and be deployed alongside your existing production line.

- Capable of inspecting a wide variety of electrical connectors

- Excellent performance and reliable inspection results for low contrast or dark electrical connectors

- Allowable harness angle variation ≤ ±20°

- Allowable seat stop position variation ≤ ±50mm

Powerful Inspection Capabilities

Bluewrist seat inspection solution can quickly and reliably check the following features to ensure defect free delivery to your customer:

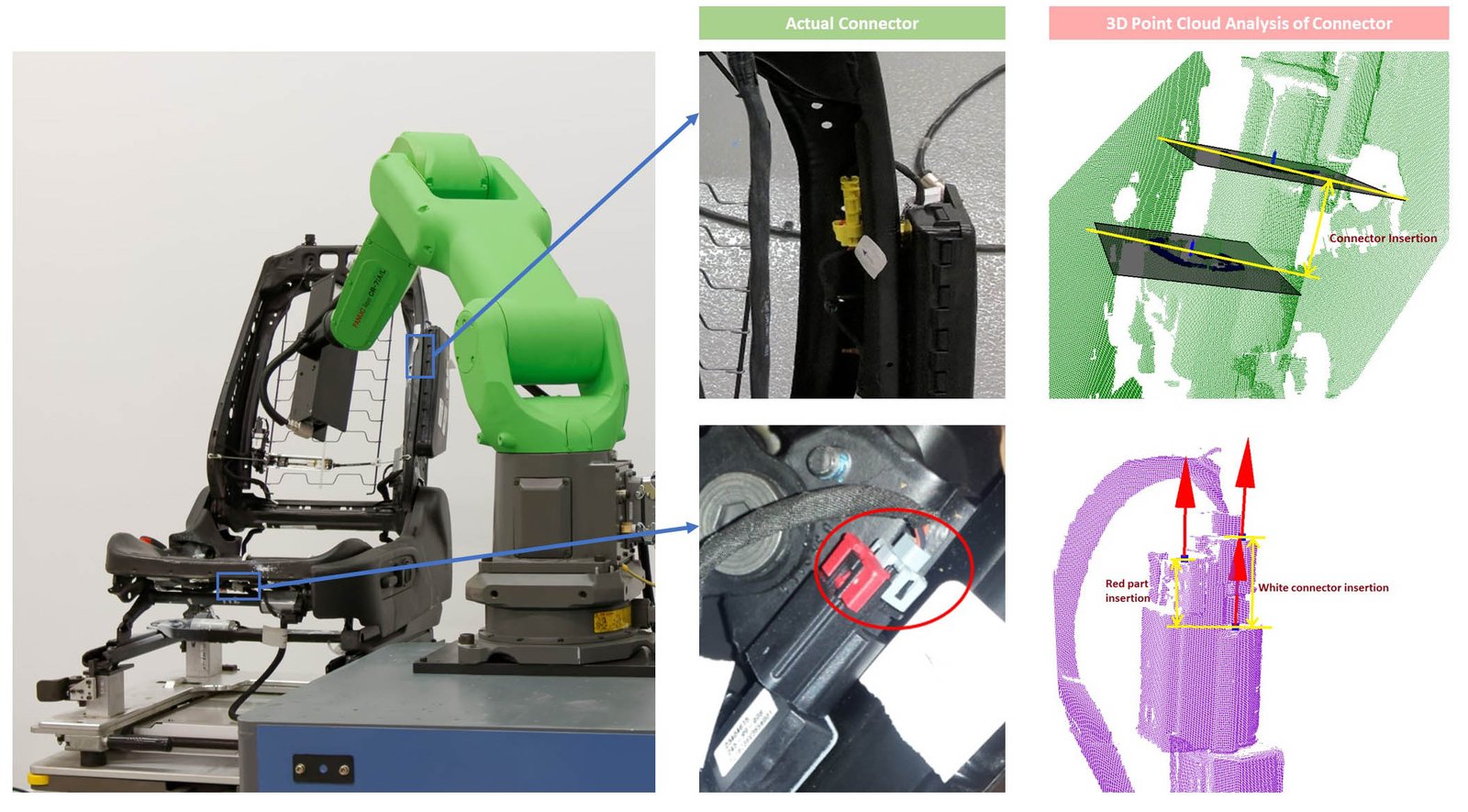

3D Point Cloud Processing and Analysis of Scanned Feature – Checking Clip Height Insertion

Seat Harness Inspection with 3D Vision

The Bluewrist Seat Harness Inspection Solution uses a high-resolution 3D structured light scanner to capture a detailed point cloud of the seat harness connectors. The 3D point cloud is analyzed by our NIST-Certified ScanXtream software to discern the completeness of insertion. With a resolution of up to 0.1mm, the slightest out of tolerance clip insertion is automatically flagged and logged as a defect for rework, which adequately eliminates downstream defects.

Examples of challenging wiring harness that the Bluewrist solution can inspect for complete insertion.

Real-time Insight Into Your Manufacturing Process

The Bluewrist Seat Inspection Solution provides users a visual indication of defects in the electrical harness based on the user-configured datum and quality standard parameters. Reports can be saved for future reporting, record keeping and review purposes as part of a comprehensive quality assurance program.

By checking every electrical harness throughout the manufacturing process, trends and custom alarms will notify you of potential problems before it leads to downstream defect:

- In this SPC chart on the right, the clip insertion height is regular until the 3D vision system detects an incorrect insertion

- Operators are automatically alerted, and the defect location is indicated graphically for rework and inspection

Technical Specifications:

- Cycle Time – 2.5 seconds per harness(average)

- Inspection dimensional accuracy – ≤±1mm

- Maximum sensor field of view – 154x100x110mm

Predictive Defect Analysis and Notification