Fast ROI through reduction in QA inspection and rework time cost.

Reduce downstream part defects that may lead to safety recalls.

Full traceability and insights into your manufacturing process.

Achieve 100% inline inspection of all your parts and dimensional features.

Deliver defect-free products through 100% inline inspection

Field-proven and trusted by the world’s top manufacturers in the automotive and healthcare sectors, Bluewrist offers turn-key 3D machine vision system that are tailored to your manufacturing environment and project needs.

CONTACT US FOR MORE INFORMATION

Surface defects

Feature Presence

Connector Insertion

Dimensional Tolerance

Anything Less than 100% is a compromise – Don’t Leave Quality Control to Chance

If your quality control process relies on manual inspection (through sampling or physical measurements), you risk passing defective parts downstream or to the end customer. Using Bluewrist’s turn-key inline inspection solutions, it is easy to transform from manual to a fully automated 100% inline quality control process.

Bluewrist is a Leader in 3D Machine Vision System

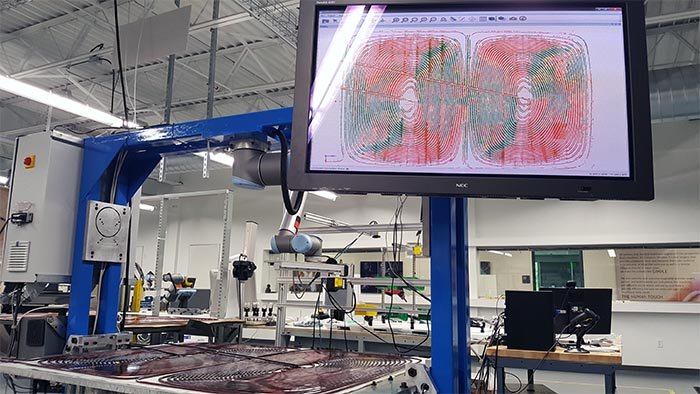

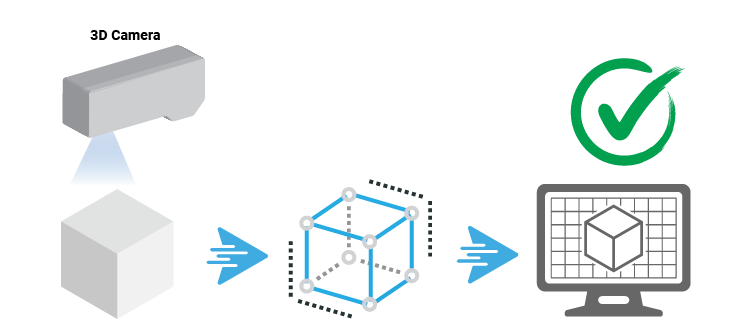

Bluewrist’s inline inspection solution uses a 3D profiler, or 3D snapshot sensors (such as the Gocator® 3D smart sensors), to capture detailed data on all parts. Next, we process the 3D point cloud data through our ScanXtream software, using techniques such as dimensional comparison, machine learning, and artificial intelligence to identify defects.

Leveraging over 15 years of combined experience, our team will work with you to design a complete solution that enables 100% inline inspection of all parts made. By working with us, you can rest assured that no defective parts or products will be passed downstream – avoiding expensive recalls and safety risks to the end user.

Working with Bluewrist is Easy!

From One to Dozens of Cameras – We can meet any inspection needs

Powered by our custom-developed ScanXtream software, Bluewrist’s 3D machine vision system offers superior performance and scalability to meet any project requirements.

From an entry-level single camera fixed inspection and multiple-camera robotic inspections to covering large complex parts, we have the expertise to fulfill all of your inspection needs.

NIST Certified Software and Inspection Algorithm

Bluewrist ScanXtream software algorithm and methodology is NIST certified. This ensures that the inspection result is accurate and repeatable for critical manufacturing quality control needs.

Predictive Analysis to Prevent Defects at the Source

By deploying a Bluewrist 100% inline inspection solution for your manufacturing process, you will gain real-time insights into your production process through our SPCWorks software. After thoroughly analyzing every feature involved in the manufacturing process, trends and custom alarms will inform you of potential problems and enable you to avoid costly defects.

Benefits Include:

- Prevent defects at the source– detects and reports deviations in dimensional variations and takes preventative action to minimize defects

- Monitor and analyze trends in the production process– statistically analyzes dimensional data for all scanned parts and automatically notifies users of deviations from predetermined tolerances

- Real-time quality data to improve traceability– in-line or near-line deployment to gather real-time quality data for rapid decision making

Bluewrist & LMI Inline Inspection Success Stories

Bluewrist’s 100% inline 3-D vision inspection solution, powered by LMI Gocator® 3D Smart Sensor, can be found in factories around the world. Working 24/7, it inspects each part to ensure your customers benefit from the highest quality product.

Some of our notable customers include:

Download the case studies on the left to learn more about our customer success stories.

We Tackle the Toughest Inspection & Quality Control Jobs

Over the past 15 years, Bluewrist has tackled the most challenging 100% inline inspection projects for top manufacturers worldwide. Prior to implementing our solutions, many of our customers relied on manual visual inspections. Not only is this method insufficient, it greatly increases the risk of passing defective parts downstream. Undetected, these defects can lead to catastrophic product failures, safety issues, and/or expensive product recalls.