Quality Assurance Solutions for 3D Bead Inspection

Bluewrist 3D Bead Inspection – Ensuring Precision in every Bead

100% visual inspection and dimensional quality information

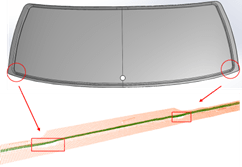

Bluewrist 3D Bead Inspection system inspects the quality of adhesive, sealant, and glue deposits to ensure the correct dimension, location, and continuity of the bead. The system analyzes imperfections at width, height, location, discontinuity, and volume within the standard manufacturer specifications. It can manage interference by other objects, such as sealing felt or clips. The real-time SPC lets customers easily report, analyze, and control the entire process.

Bead Inspection can be available in two different configurations:

- Using Snapshot Cameras

- Using Profiler Cameras

The Snapshot configuration uses one or multiple snapshot cameras (3D structured light cameras) to scan the bead and qualify its quality. The snapshot camera is typically stationary but can also be mounted to a robot arm.

The Profiler configuration uses 3D profilers mounted to the dispenser head which can be mounted to a robot arm or stationary.

Features

- Assess the width, measure height dimensions, detect defects, and locate gaps.

- Identify defects in beads with changing shapes.

- Improve robustness by filtering out noise.

- Quickly set the bead profile using a few clicks with the dataset.

- Integrate with machine learning models to enhance defect detection accuracy.

Benefits

- Automated 100% features inline inspection, not missing bad parts.

- Ensures an adequate bead volume is applied to the surface, which meets manufacturer specifications for bond strength or seal requirements.

- Catches defects early in the manufacturing process to prevent a more expensive recall or safety issue.

- It outperforms the 2D inspection solution because 3D inspection could reliably measure fresh bead surfaces that are often reflective, as well as be independent of the bead color.

- Fully integrated with the line PLCs and robots for alarming and decision making using our comXtream engine

- Provides dimensional measurement and a variety of defect detection, not just presence checks.

- Centralized database (on-prem or cloud) allowing remote access and sharing data between systems.

- Plant-wide production data access for built-quality monitoring and report generation.

- Offers traceability and Statistical Process Control (SPC) for assembly quality analysis.

OPTIMIZING INSPECTION

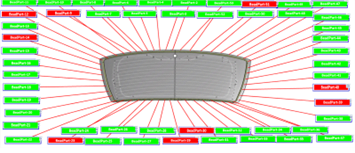

ScanXtream ensures top-notch quality assurance, whether it inspects 3D or 2D beads. It will check the quantity and qualitative examination of feature traits and their presence/absence on a target part. The Bluewrist software applies volume of interest (VOI) to filter out unwanted features, such as sealing felt,

ScanXtream ensures top-notch quality assurance, whether it inspects 3D or 2D beads. It will check the quantity and qualitative examination of feature traits and their presence/absence on a target part. The Bluewrist software applies volume of interest (VOI) to filter out unwanted features, such as sealing felt,

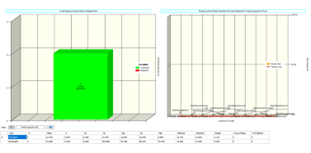

REAL-TIME INSIGHTS FOR 3D BEAD INSPECTION

Bluewrist 3D bead inspection technology generated a full 3D image within SPCWorks software. Each windshield’s bead measurement values are updated in real-time, with actual measurement and out-of-tolerance values. SPCWorks provides trends and historical data, visualizes it through graphs, charts, and tables, and ensures that dashboards can be developed accordingly. This analysis process sets the highest quality standards for adhesive dispensing.